Table of Contents

ToggleFile cabinet technology Laying the foundation for precision molding process

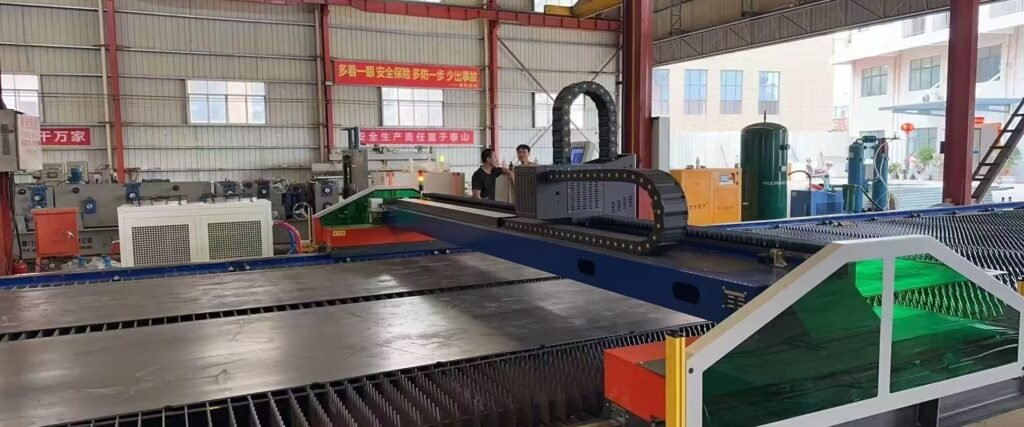

The forming of File cabinet technology begins with a precision metal processing process, which mainly includes three core processes: cutting, stamping and bending. Modern production first through the laser cutting technology to complete the plate cutting, compared with the traditional shearing machine, laser cutting can achieve ±0.1mm precision control, to ensure that the door, side plate and other components of the size accurate match. After the basic cutting is completed, the positioning holes, lock holes and decorative lines are punched out on the plate by the CNC stamping device, especially the installation holes of the drawer guide rails. The error is required to be no more than 0.3mm.

As the key link of forming, the bending process is operated by multi-axis CNC bending machine. Depending on the structural requirements of different parts of the file cabinet, the technician will preset 12 to 16 different sets of bending parameters: the side panel needs to be bent at a 90° right Angle to ensure perpendicularity, the door panel uses a gradual bending with curvature to enhance deformation resistance, and the back panel is usually bent at a shallow Angle to reserve assembly clearance. This differentiated treatment allows cold rolled steel plates with a thickness of 0.6-1.2mm to maintain structural strength while forming precise assembly interfaces.

Technical breakthrough of bending process

Modern bending technology adopts three-point CNC bending technology. Through the cooperative work of upper die, lower die and pressure sensor, the bending Angle tolerance can be controlled within ±0.5°. For the L-shaped corner structure unique to the filing cabinet, it is necessary to use a segmental bending process: the main bending line is completed first, and then the secondary molding is carried out by the side push mold. This process can maintain the continuity of the steel fiber at the corner, and improve the structural strength by 30% compared to the traditional single bending.

In the processing of precision parts such as drawer guides, the factory introduces the rolling bending composite process. The steel plate is prebent through 12 sets of rollers and then shaped by CNC bending machine. This combination process can eliminate the phenomenon of material rebound and make the straightness of the guide rail reach the industry high standard of 0.15mm/m. For special modeling needs, some high-end file cabinets will use oil-electric hybrid bending machine, adding hydraulic fine adjustment system on the basis of conventional pneumatic bending, to achieve high-precision forming of complex surfaces.

3.Welding and surface pretreatment

The bent components enter the automatic welding process, using carbon dioxide shielded welding and spot welding combined process. For major load-bearing structures such as column frames, continuous welds are used to ensure strength; The appearance of the surface adopts the non-trace spot welding technology, and the solder joint spacing is controlled at 25-30mm, which not only ensures the connection strength but also keeps the surface flat. After welding, the cabinet needs to be pickling and phosphating treatment, and form a 5-8μm phosphate crystal layer on the surface of the steel plate through 8 chemical tank circulation, which can increase the subsequent spray adhesion by 60%.

4.Assembly quality control system

In the final assembly stage, the bending accuracy directly affects the assembly efficiency. Using modular assembly process, the pre-bent side panels, top plate and bottom plate are quickly positioned through the buckle structure, and then finally fixed with self-tapping screws. Professional quality inspection includes bending Angle verification, hole position moderate test and opening and closing fatigue test to ensure that each bending structure can meet the standard requirements of 100,000 drawer opening and closing. Finally, the coating thickness at the bending edge of the cabinet body treated by electrostatic spraying should reach 80-120μm, and the anti-corrosion performance is verified by salt spray test.

In SUMMARY

This production system, which integrates precision bending technology and modern manufacturing process, not only ensures the structural stability of the steel filing cabinet, but also realizes the precise control of the appearance of the line. From the office to the archive warehouse, the scientifically designed bending structure allows each file cabinet to maintain excellent mechanical properties in long-term use, fully demonstrating the perfect combination of metal processing technology and modern industrial design.