Table of Contents

ToggleAnalysis of powder spraying technology on metal file cabinet surface

As the basic equipment in the modern office scene, the surface treatment process of metal file cabinet directly affects the service life and appearance texture of the product. Powder spraying technology with its environmental characteristics and excellent coating effect, has become the mainstream process of metal filing cabinet manufacturing industry. In this paper, the core process of powder spraying in metal file cabinet production will be analyzed according to the characteristics of file cabinet products.

Substrate pretreatment process optimization

The main body of the file cabinet is mostly made of cold-rolled steel plate or galvanized steel plate, and the pretreatment stage needs to focus on solving the problem of oil residue andoxidation on the metal surface. The production line generally adopts a three-step treatmentmethod: first by alkaline degreaser to remove the residual oil from the stamping, followed bythe use of zinc phosphate conversion film treatment to improve the rust resistance of thesubstrate, and finally the use of pure water cleaning to ensure surface cleanliness. For high-endfile cabinet products, the additional sandblasting process can effectively enhance the coatingadhesion, and the treated surface roughness is controlled at Sa2.5 level, which can ensure thepowder adsorption effect without affecting the final surface smoothness. The pre-treatedworkpiece needs to enter the spraying process within 4 hours to avoid secondary oxidationaffecting the coating quality.

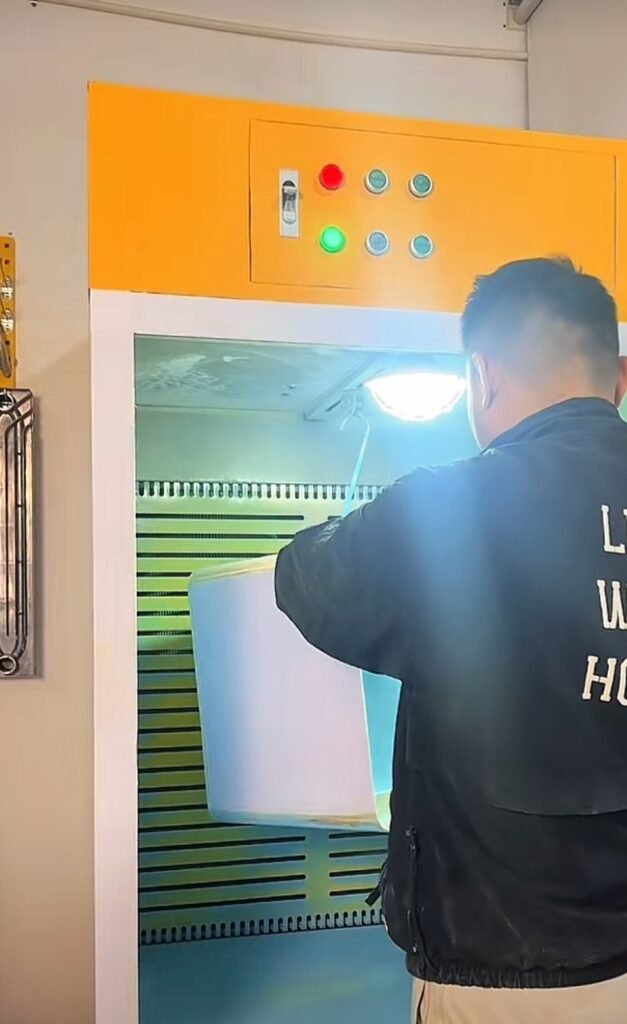

Electrostatic spraying process control points

The box structure of metal file cabinet has the characteristics of coexistence of large area plane and bent groove, which puts forward double technical requirements for spraying process. The mainstream production line adopts a composite spraying scheme combining corona charging and friction charging: the plane area uses a corona charging spray gun to achieve more than 95% powder rate to ensure uniform coating thickness; For complex structures such as door panel flanges and drawer slides, Tribo friction charging devices are switched to achieve complete coverage of corners by using directional charge characteristics. To meet the needs of different scenarios, the spray line is equipped with an adjustable suspension conveying system, the standard line speed is controlled in the range of 2.5-3.2m/min, and the Wagner intelligent powder supply system can reach a single spray thickness of 60-80μm. The specially designed recovery unit can increase the recovery rate of oversprayed powder to 98%, significantly reducing material loss.

Curing process parameter setting

In the initial stage, the coating is heated up to 160℃ at the rate of 10℃/min, so that the mixed powder of epoxy-polyester is fully melted and levelled. In the second stage, the crosslinking reaction is completed by maintaining a constant temperature at 190℃ for 15 minutes. This process design can not only ensure that the coating reaches the wear-resistant standard of pencil hardness 2H, but also avoid heat deformation of the box sheet. For the composite cabinet with plastic parts, the powder can be cured at 130 ° C at low temperature, and the workpiece temperature can be reduced to below 50 ° C within 90 seconds with the forced air cooling system, which effectively protects the performance of plastic parts. After testing and verification, the optimized curing process can make the file cabinet coating pass the 500-hour salt spray test, and fully meet the durability requirements of office furniture.

Process advantage and quality control

Compared to traditional liquid spraying, powder spraying offers significant advantages in the manufacture of file cabinets. The solvent-free feature completely solves the VOC emission problem, the increase in coating density increases the impact resistance by 40%, and the incidence of orange peel phenomenon is reduced to less than 3%. The production line is equipped with an online detection system to monitor the coating uniformity in real time through the laser thickness gauge, and the color difference meter ΔE value is strictly controlled within 0.8. The finished file cabinet is verified by both the falling ball impact test (500g steel ball 1m free fall) and the 100-bar adhesion test (ASTM D3359 standard) to ensure that the product meets commercial quality standards. Practical data show that the service life of the file cabinet using powder spraying process can be extended to more than 10 years, and the maintenance cycle is 3 times longer than that of traditional paint products.

With the popularization of intelligent manufacturing technology, the powder spraying process of metal file cabinets is developing in the direction of digitalization and flexibility. Through the construction of process parameter database and the application of AI visual inspection system, the entire process of spraying quality traceability is realized, and energy consumption is reduced by more than 15% while improving product consistency. This green manufacturing model not only conforms to the concept of sustainable development, but also enables steel filing cabinets to achieve quality upgrades.